Oil seals—sometimes called shaft seals or rotary seals—play a crucial role in protecting mechanical systems from leaks and contamination. Found in engines, pumps, gearboxes, and countless industrial machines, these small but powerful components prevent oil from escaping while keeping dirt, dust, and water out.

How Oil Seals Work

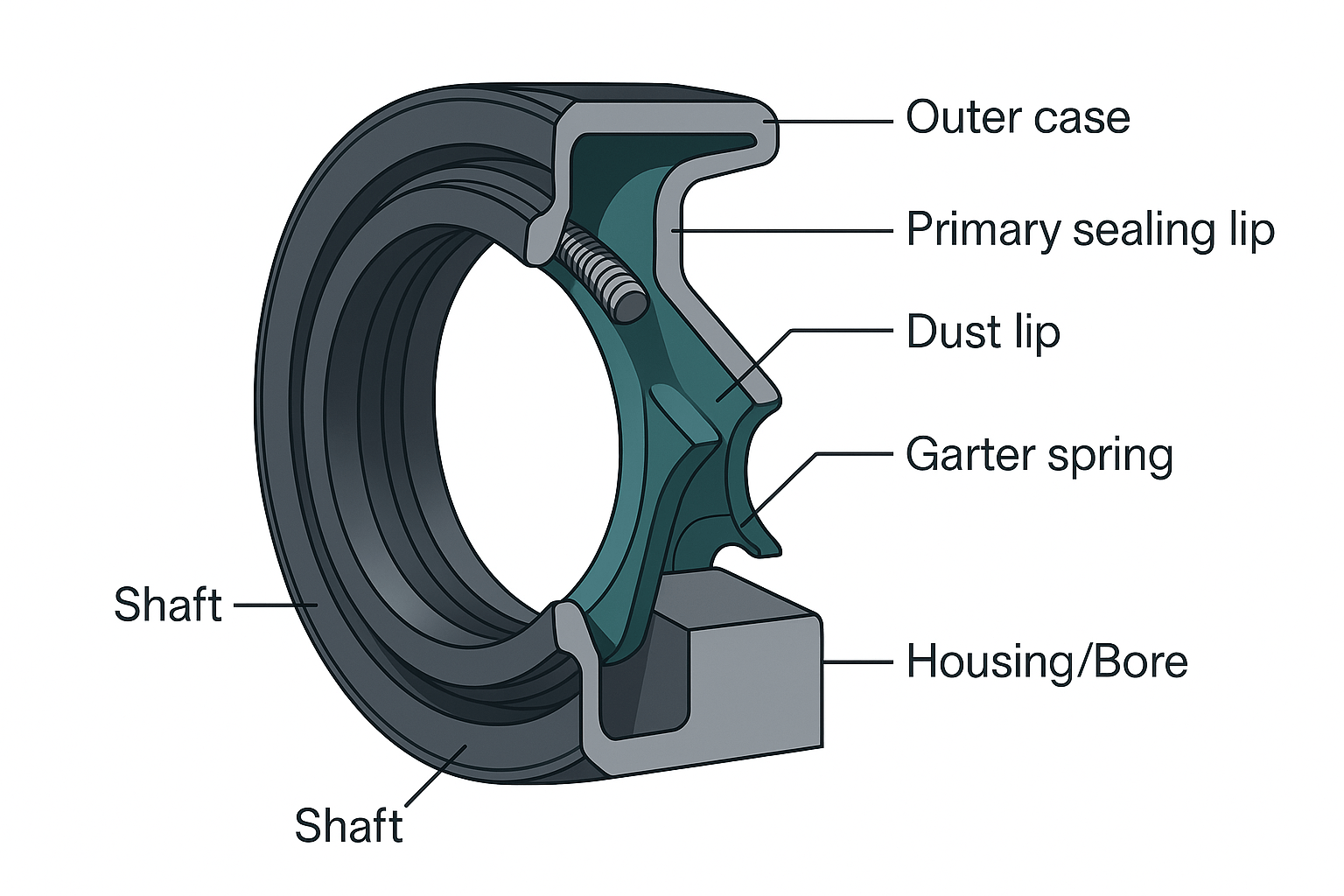

An oil seal fits tightly around a rotating shaft and the housing it passes through. The flexible lip of the seal maintains contact with the shaft surface, creating a barrier that holds lubricant in place while allowing rotation. The result: smoother operation, reduced friction, and extended bearing life.

Key Components

-

Outer Case: Provides structural rigidity and fits snugly in the bore.

-

Sealing Lip: The flexible edge that contacts the shaft surface.

-

Garter Spring: Helps maintain sealing pressure around the shaft.

Common Materials

-

Nitrile (NBR): Excellent resistance to oil and grease; ideal for general industrial use.

-

Viton (FKM): Handles higher temperatures and aggressive chemicals.

-

Silicone: Performs well in extreme temperatures and clean environments.

Where Oil Seals Are Used

You’ll find oil seals in:

-

Small engines (lawnmowers, ATVs)

-

Automotive drivetrains and wheel hubs

-

Pumps and compressors

-

Industrial gearboxes

Why Quality Matters

Low-grade seals can harden or tear over time, leading to costly leaks and downtime. Premium options from AVX Seals are precision-engineered to withstand demanding applications and extend the lifespan of your machinery.